Work process

Since the alliance with Flexitallic Investments Inc. we have developed and improved our manufacturing and distribution processes.

We adopted the Flexitallic safety approach as a guide to focus our operations, product design and customer service.

Doing business securely

INNOVATE

We have a global team of engineers, chemists and technicians working to develop new products and materials and constantly improve our existing products.

Our efforts are supported by two state-of-the-art laboratories in the United Kingdom and the United States.

Our efforts are supported by two state-of-the-art laboratories in the United Kingdom and the United States.

CUSTOMIZE

Sealing solutions that have been customized for your specific application are more likely to be effective.

Our expert engineers work closely with the Flexitallic team to develop a new solution or improve an existing one.

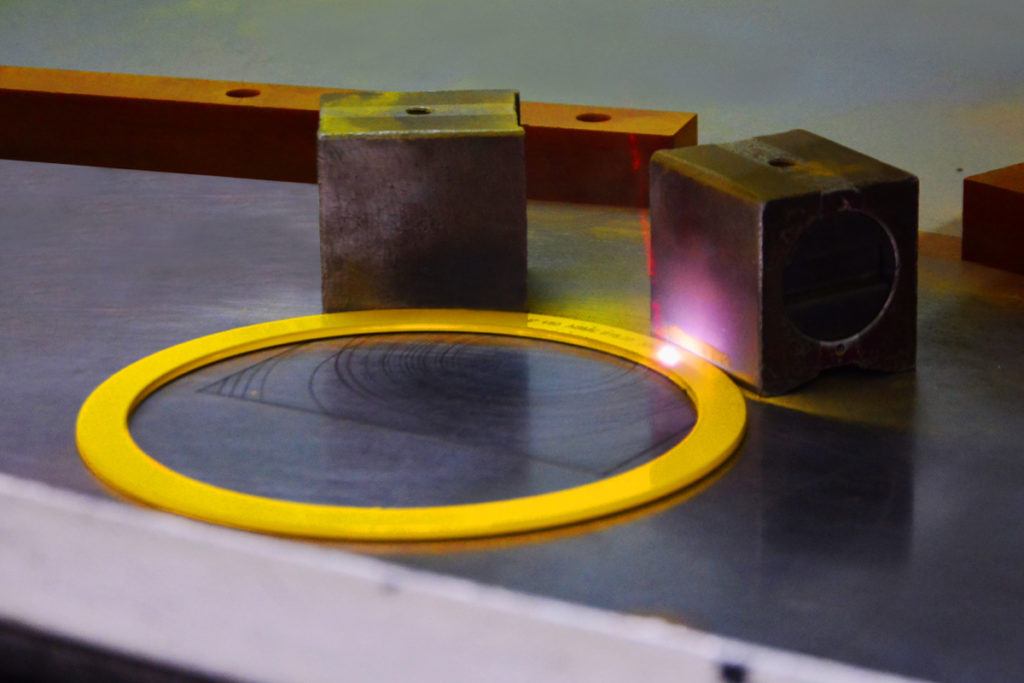

The combination of rigorous design, advanced materials and our high manufacturing standards make for a more effective and safer sealing solution.

Our expert engineers work closely with the Flexitallic team to develop a new solution or improve an existing one.

The combination of rigorous design, advanced materials and our high manufacturing standards make for a more effective and safer sealing solution.

EDUCATE

Many flange failures are the result of improper installation.

This is one of the reasons why safety and environmental problems can be caused in industries where toxic chemicals, pressure and extreme heat are used.

To address this problem we have created the Joint Integrity Academy.

Our expert trainers, who provide training on gasket installation and gasket integrity, work to the latest industry standard guidelines.

We visit plants around the world to educate their new and experienced engineers, giving them the practical skills they need to perform this critical procedure correctly.

This is one of the reasons why safety and environmental problems can be caused in industries where toxic chemicals, pressure and extreme heat are used.

To address this problem we have created the Joint Integrity Academy.

Our expert trainers, who provide training on gasket installation and gasket integrity, work to the latest industry standard guidelines.

We visit plants around the world to educate their new and experienced engineers, giving them the practical skills they need to perform this critical procedure correctly.

Manufacturing Capacity

The Guadalajara facility is equipped with state-of-the-art machinery and equipment. The new machines are computer numerically controlled (CNC) which helps to increase production and ensure better quality standards. EQUITER has no limitations in its capabilities.